Carbide Tubing Expanders

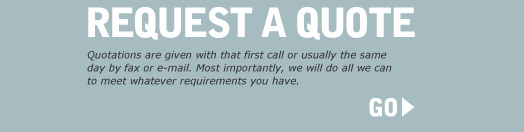

The tubing expanders that we provide are solid tungsten carbide. The material is a C2 grade, with a submicron particle size and hardness on the Rockwell 'C' scale in the low 90's. The exterior wear area is polished to a high shine to minimize friction and maximize wear as well as hold the OD tolerance to a few ten-thousands of an inch. This material will tremendously outperform similar tool steel products that offer a very thin wear coating and a significantly softer substrate.

Venting can be provided in the form of vent grooves or channels on the ends to prevent a build-up of head pressure during the expansion process. This is generally needed only for smooth wall tubing, but can be utilized to differentiate expander sizes as well.

We presently provide both hemispherical and tapered expanders in a variety of sizes. If your requirement is different from our existing tooling, a new form can be generated relatively quickly, usually in 3 to 4 weeks.

|

|

Coatings: PVD coatings such as Titanium Nitride (TiN), are available for performance and identification.

Bushings: Bushings are available for the 0.187" I.D. parts that allow the tubing expander to spin. This works well with rifled tubing.

Screws: Attachment screws are available with altered heads and venting if required.

|